- Steber Steel Solutions is the world's premier Exporter of Fittings, Flanges, Pipes, Sheet & Plate etc.

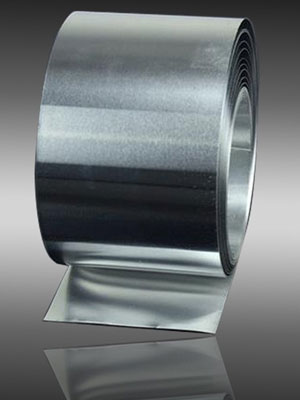

Incoloy 800/800H/800HT Sheet & Plate

- home

- Incoloy Sheet & Plate

Largest Stockists of UNS N08800 Coils, Biggest Alloy 800 Sheets & Plates, DIN 1.4876 Polished Plates, Incoloy 800 Sheets, Incoloy Alloy 800H HR Plates, Alloy 800HT Coils Manufacturer In India.

Steber Steel Solutions is a known trader and seller of Incoloy 800 / 800H / 800HT Sheets & Plates, which exhibits excellent resistance to corrosion in environments containing hydrogen sulfide (H2S), commonly referred to as sour gas corrosion. This type of corrosion is particularly challenging in the oil and gas industry, where Incoloy 800 is extensively used. The alloy's resistance to sour gas corrosion makes it suitable for downhole equipment, wellhead components, and piping systems in oil and gas exploration and production.

Incoloy UNS N08800 Plates demonstrates resistance to intergranular corrosion, which can occur in certain environments when exposed to high temperatures. The alloy's solid solution strengthening and controlled carbon content contribute to its ability to resist intergranular corrosion, ensuring the material's long-term reliability and performance.

We provide the best quality UNS N08810 Hot Rolled Sheets Specification Standard, Incoloy 800 Cold Rolled Plates, werkstoff 1.4876 Shim Sheets, Pure Incoloy 800H Sheets Stockist.

Incoloy WNR 1.4876 Sheets offers excellent resistance to corrosion in various aqueous environments, including saltwater, brackish water, and industrial process water. Its resistance to localized corrosion phenomena, such as pitting and crevice corrosion, ensures the alloy's durability and integrity even in challenging conditions. Incoloy UNS N08810 Plates is resistant to corrosion in acidic gas environments, such as those encountered in flue gas desulfurization systems, chemical plants, and exhaust systems. Its ability to withstand the corrosive effects of acidic gases, including sulfur dioxide (SO2) and hydrogen chloride (HCl), makes it suitable for applications in these industries.

Incoloy UNS N08811 Sheets maintains its corrosion resistance even at elevated temperatures. It exhibits excellent stability and resistance to degradation in high-temperature environments, such as those encountered in gas turbines, heat exchangers, and aerospace applications. It as well has resistant to soaring temperature erosion and sustained exposure. Known as Incoloy WNR 1.4959 Plates, we also offer the same at made-to-order shapes and sizes to our esteemed clients.

Incoloy 800/800H/800HT Sheets & Plates Secifications

| Specifications | ASTM B409 / ASME SB409, BS EN 10088-2, en 10028-7, IS 6911 |

|---|---|

| Dimension Standard | MSRR, AMS, BS, JIS, AISI, ASTM, GB, DIN, EN, etc |

| Size Range | Cold rolled Plate 0.5-6.4 mm Hot rolled Plate 3.0–10.0 mm |

| Width | 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc |

| Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc |

| Thickness | 0.3 mm to 120 mm |

| International Standard | ASTM A480 ASTM A959 ASME IID EN ISO 9445 EN ISO 18286 EN 10051 EN 10088-1 ISO 15510 |

| Tolerances (width / thickness) | EN 10258/ DIN 59381) EN 10151 EN 10088 |

| Finish | 2B, 2D, BA NO (8), Cold rolled Plate (CR), Hot rolled plate (HR), SATIN (Met with Plastic Coated), No.1 finish hot rolled, 1D, 2B, No.4, BA, 8K, satin, hairline, brush, mirror etc. |

| Hardness | Half Hard, Soft, Hard, Quarter Hard, Spring Hard |

| Value Added Service | Cladding, Heat Treatment, Annealed, Pickling, Polish, Rolling, Cutting, Bending, Forging, Minor Fabrication Etc. |

| Dealers & Distributor of | SAIL, ESSAR, TATA, BHUSHAN, INDIAN, POSCO, JISCO, TISCO, LISCO, BAOSTEEL IMPORTED material |

| Profiling | Plasma Plate Cutting Laser Plate Cutting Oxy-propane Flame Cutting |

Inconel Sheets & Plates sGrades

| Inconel 600 Sheets & Plates | Inconel 601 Sheets & Plates | Inconel 625 Sheets & Plates | |

| Incoloy 800/800H/800HT Sheets & Plates | Incoloy 825 Sheets & Plates | Incoloy 925 Sheets & Plates |

Incoloy 800/800H/800HT Sheets & Plates Types

Incoloy Alloy 800/800H/800HT Sheets & Plates Equivalent Grade

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN | OR |

| Incoloy 800 | 1.4876 | N08800 | NCF 800 | NA 15 | ЭИ670 | Z8NC32-21 | X10NiCrAlTi32-20 | XH32T |

| Incoloy 800H | 1.4958 / 1.4876 | N08810 | NCF 800H | NA 15(H) | ЭИ670 | Z8NC33-21 | X5NiCrAlTi31-20 | XH32T |

| Incoloy 800HT | 1.4859 / 1.4876 | N08811 | NCF 800HT | NA 15(HT) | ЭИ670 | – | X8NiCrAlTi32-21 | XH32T |

Buy Alloy 800 Sheet online, Check ASME SB409 Incoloy 800H Plate Price List here. Stock of Incoloy Alloy 800HT Coils in Mumbai.

Thickness Chart OF Incoloy 800/800H/800HT Sheets

| Thickness | Thickness | Size Range | Surface Area per Unit weight | Approx Weight per Sheet | ||

|---|---|---|---|---|---|---|

| inches | mm | lbs/ft² | kg/m² | lbs | kg | |

| 0.015 | 0.381 | 36 x 96 | 0.630 | 3.07566 | 15.12 | 6.84936 |

| 0.015 | 0.381 | 36 x 120 | 0.630 | 3.07566 | 18.90 | 8.5617 |

| 0.0178 | 0.45212 | 36 x 96 | 0.756 | 3.690792 | 18.15 | 8.22195 |

| 0.0178 | 0.45212 | 36 x 120 | 0.756 | 3.690792 | 22.68 | 10.27404 |

| 0.0178 | 0.45212 | 48 x 96 | 0.756 | 3.690792 | 24.19 | 10.95807 |

| 0.0178 | 0.45212 | 48 x 120 | 0.756 | 3.690792 | 30.24 | 13.69872 |

| 0.0235 | 0.5969 | 30 x 96 | 1.008 | 4.921056 | 20.16 | 9.13248 |

| 0.0235 | 0.5969 | 30 x 120 | 1.008 | 4.921056 | 25.20 | 11.4156 |

| 0.0235 | 0.5969 | 36 x 96 | 1.008 | 4.921056 | 24.19 | 10.95807 |

| 0.0235 | 0.5969 | 36 x 120 | 1.008 | 4.921056 | 30.24 | 13.69872 |

| 0.0235 | 0.5969 | 36 x 144 | 1.008 | 4.921056 | 36.29 | 16.43937 |

| 0.0235 | 0.5969 | 48 x 96 | 1.008 | 4.921056 | 32.26 | 14.61378 |

| 0.0235 | 0.5969 | 48 x 120 | 1.008 | 4.921056 | 40.32 | 18.26496 |

| 0.0235 | 0.5969 | 48 x 144 | 1.008 | 4.921056 | 48.39 | 21.92067 |

| 0.0291 | 0.73914 | 30 x 96 | 1.260 | 6.15132 | 25.20 | 11.4156 |

| 0.0291 | 0.73914 | 30 x 120 | 1.260 | 6.15132 | 31.50 | 14.2695 |

| 0.0291 | 0.73914 | 36 x 96 | 1.260 | 6.15132 | 30.24 | 13.69872 |

| 0.0291 | 0.73914 | 36 x 120 | 1.260 | 6.15132 | 37.80 | 17.1234 |

| 0.0291 | 0.73914 | 36 x 144 | 1.260 | 6.15132 | 45.37 | 20.55261 |

| 0.0291 | 0.73914 | 48 x 96 | 1.260 | 6.15132 | 40.32 | 18.26496 |

| 0.0291 | 0.73914 | 48 x 120 | 1.260 | 6.15132 | 50.41 | 22.83573 |

| 0.0291 | 0.73914 | 48 x 144 | 1.260 | 6.15132 | 60.49 | 27.40197 |

| 0.0355 | 0.9017 | 30 x 96 | 1.512 | 7.381584 | 30.24 | 13.69872 |

| 0.0355 | 0.9017 | 30 x 120 | 1.512 | 7.381584 | 37.80 | 17.1234 |

| 0.0355 | 0.9017 | 36 x 96 | 1.512 | 7.381584 | 36.29 | 16.43937 |

Thickness Chart OF Incoloy 800/800H/800HT Plates

| Thickness | Thickness | Size Range | Surface Area per Unit weight | Approx Weight per Sheet | ||

|---|---|---|---|---|---|---|

| inches | mm | lbs/ft² | kg/m² | lbs | kg | |

| 0.015 | 0.381 | 36 x 96 | 0.630 | 3.07566 | 15.12 | 6.84936 |

| 0.015 | 0.381 | 36 x 120 | 0.630 | 3.07566 | 18.90 | 8.5617 |

| 0.0178 | 0.45212 | 36 x 96 | 0.756 | 3.690792 | 18.15 | 8.22195 |

| 0.0178 | 0.45212 | 36 x 120 | 0.756 | 3.690792 | 22.68 | 10.27404 |

| 0.0178 | 0.45212 | 48 x 96 | 0.756 | 3.690792 | 24.19 | 10.95807 |

| 0.0178 | 0.45212 | 48 x 120 | 0.756 | 3.690792 | 30.24 | 13.69872 |

| 0.0235 | 0.5969 | 30 x 96 | 1.008 | 4.921056 | 20.16 | 9.13248 |

| 0.0235 | 0.5969 | 30 x 120 | 1.008 | 4.921056 | 25.20 | 11.4156 |

| 0.0235 | 0.5969 | 36 x 96 | 1.008 | 4.921056 | 24.19 | 10.95807 |

| 0.0235 | 0.5969 | 36 x 120 | 1.008 | 4.921056 | 30.24 | 13.69872 |

| 0.0235 | 0.5969 | 36 x 144 | 1.008 | 4.921056 | 36.29 | 16.43937 |

| 0.0235 | 0.5969 | 48 x 96 | 1.008 | 4.921056 | 32.26 | 14.61378 |

| 0.0235 | 0.5969 | 48 x 120 | 1.008 | 4.921056 | 40.32 | 18.26496 |

| 0.0235 | 0.5969 | 48 x 144 | 1.008 | 4.921056 | 48.39 | 21.92067 |

| 0.0291 | 0.73914 | 30 x 96 | 1.260 | 6.15132 | 25.20 | 11.4156 |

| 0.0291 | 0.73914 | 30 x 120 | 1.260 | 6.15132 | 31.50 | 14.2695 |

| 0.0291 | 0.73914 | 36 x 96 | 1.260 | 6.15132 | 30.24 | 13.69872 |

| 0.0291 | 0.73914 | 36 x 120 | 1.260 | 6.15132 | 37.80 | 17.1234 |

| 0.0291 | 0.73914 | 36 x 144 | 1.260 | 6.15132 | 45.37 | 20.55261 |

| 0.0291 | 0.73914 | 48 x 96 | 1.260 | 6.15132 | 40.32 | 18.26496 |

| 0.0291 | 0.73914 | 48 x 120 | 1.260 | 6.15132 | 50.41 | 22.83573 |

| 0.0291 | 0.73914 | 48 x 144 | 1.260 | 6.15132 | 60.49 | 27.40197 |

| 0.0355 | 0.9017 | 30 x 96 | 1.512 | 7.381584 | 30.24 | 13.69872 |

| 0.0355 | 0.9017 | 30 x 120 | 1.512 | 7.381584 | 37.80 | 17.1234 |

| 0.0355 | 0.9017 | 36 x 96 | 1.512 | 7.381584 | 36.29 | 16.43937 |

Most Selling Types Of Incoloy 800/800H/800HT Sheets & Plates

- Incoloy® Alloy 800HT Coils

- Incoloy 800 Cold Drawn Plates Manufacturer

- UNS N08800 Plates

- ASTM B409 Incoloy 800H HR Plates

- Incoloy 800 Sheets

- Incoloy WERKSTOFF NR. 1.4958 Sheets & Coils

- UNS N08811 Shim Coils

- Alloy 800H Coils

- ANSI B16.5 Incoloy 800H Shim Sheets

- Incoloy 800 Polished Plates

- Incoloy Alloy 800HT Cold Drawn Plate

- ASME SB409 Alloy 800 Plates

- Incoloy Alloy 800HT Chequered Plate

- Grade 800 Incoloy Perforated Sheet

- Incoloy Alloy 800HT Hot Rolled Plate

- UNS N08810 Cold Rolled Sheets

- ASTM B409 Incoloy 800 Slitting Coils

- Incoloy Alloy 800H CR Plates Supplier

- Alloy 800HT Shim Sheet Stockist

- Incoloy® Alloy 800H Finish Sheet

- UNS N08800 Plates

- ASTM B409 Incoloy Alloy 800HT Chequered Sheet

- Grade 800 Incoloy Hot Rolled Plate

- Incoloy Alloy 800H Sheet Exporter

- Incoloy Alloy 800 HR Plates

- Alloy 800HT Perforated Sheets

- DIN 1.4859 Finish Strip

- UNS N08800 Foils

- Incoloy JIS NCF 800 Sheets Distributor

- Incoloy 800 Foil

- ANSI B16.5 800 Incoloy plate

- ASME SB409 Alloy 800H Plain Sheets

- UNS N08810 Chequered Plate

- Incoloy Alloy 800HT Chequered Plate

- UNS N08800 2B Finish Plates

- ASME B16.5 Incoloy 800HT Strip

- Alloy 800H Circles Stockholder

Incoloy 800/800H/800HT Sheets & Plates Chemical Composition

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr | Al | Ti |

| 800 | 0.10 max | 1.50 max | 1.00 max | 0.015 max | 0.75 max | 39.50 min | 30.00 – 35.00 | 19.00 – 23.00 | 0.15 – 0.60 | 0.15 – 0.60 |

| 800H | 0.05 – 0.10 | 1.50 max | 1.00 max | 0.015 max | 0.75 max | 39.50 min | 30.00 – 35.00 | 19.00 – 23.00 | 0.15 – 0.60 | 0.15 – 0.60 |

| 800HT | 0.06 – 0.10 | 1.50 max | 1.00 max | 0.015 max | 0.75 max | 39.50 min | 30.00 – 35.00 | 19.00 – 23.00 | 0.15 – 0.60 | 0.15 – 0.60 |

Incoloy Alloy 800/800H/800HT Sheets & Plates Mechanical Properties

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 7.94 g/cm3 | 1385 °C (2525 °F) | Psi – 75,000 , MPa – 520 | Psi – 30,000 , MPa – 205 | 30 % |

Best Supplier Of Incoloy 800/800H/800HT Sheets & Plates in Following Countries

-

Exporting Incoloy Alloy 800/800H/800HT Sheets & Plates to Below CountriesUkraine, Antananarivo, Austria, Spain, Accra, Kampala, Colombo, Mexico, UK, Jordan, Canada, Czech Republic, Taiwan, Libya, South Africa, Port Elizabeth, Lithuania, Greece, Finland, Switzerland, Omdurman, Mozabique, Estonia, Afghanistan, Maputo, Poland, Luanda, Russia, Benin, Bangladesh, Ethiopa, Subra al-Haymah, Portugal, Dakar, Iran, Tunisia, Cairo, Australia, UAE, Turkey, Japan, Italy, Brazil, Bolivia, Hong Kong, Sri Lanka, Giza, South Korea, Uganda, Lebanon, Lubumbashi, Netherlands, Iraq, Philippines, Houston, Colombia, Romania, Pretoria, Algeria, Dar es Salaam, Brazzaville, Mbuji-Mayi, Nairobi, Kolwezi, Belgium, Serbia, Port Harcourt, Myanmar, Jordon, Egypt, Addis Ababa, Israel, Bahrain, Cyprus, Tripoli, Kuwait, Kano, China, Croatia, United States, Douala, Lagos, Vietnam, Kenya, Abidjan, Netherland, Khartoum, Malaysia, South America, Saudi Arabia, Dubai, Mongolia, London, Gabon, Harare, Slovakia, Nigeria, Ouagadougou, Casablanca, Thailand (Bangkok), United Kingdom, Ecuador, Angola, Kazakhstan, Rabat, Yemen, Mogadishu, Sweden, Belarus, Austalia, Fez, Venezuela, Oman, Denmark, Mozambique, Johannesburg, United Arab Emirates, Africa, Phillipine, Bamako, India, Kuwait, Yaoundé, Azerbaijan, Kinshasa, Ghana, Durban, Costa Rica, Abu Dhabi, New Zealand, Trinidad and Tobago, Norway, Zaria, Ibadan, Bhutan, Germany, Kaduna, Indonesia, Conakry, Peru, Soweto, Freetown, Singapore, Morocco, Cameroon, Bulgaria, Chine, New York, Qatar, Cape Town, France, Sudan, Argentina, Bulawayo, Maiduguri, Hungary, Algiers, Alexandria, Pakistan.

-

Supplying Incoloy Alloy 800/800H/800HT Sheets & Plates to Following Domestic CitiesBlair, Calgary, Ho Chi Minh City, Aberdeen, Andhra Pradesh, Bansberia, Riyadh, Ulsan, Jamalpur, Madrid, Kerala, Baraut, Vung Tau, Delhi, Betul, West Bengal, Suryapet, Jeddah, Aurangabad, Nagpur, Nanded, Orissa, Courbevoie, Granada, Manipur, Secunderabad, Rio de Janeiro, Ahmedabad, Ludhiana, Waghala, Muscat, Patna, Hanoi, Caracas, La Victoria, Allahabad, Busan, India, Atyrau, Loni, Ambala, Udgir, Haryana, Muktsar, Karnataka, Tamil Nadu, Kurnool, Chandigarh, Assam, Jamnagar, Thiruvananthapuram, Mizoram, Guntur, Jodhpur, Tirunelveli, Kanpur, Dombivali, Bikaner, Howrah, Bogota, Meerut, Saharanpur, Guwahati, Kalyani, Gurgaon, Jabalpur, Dammam, Dehradun, Faridabad, Solapur, Santiago, Indore, Rajkot, Geoje-si, Dallas, Vijayawada, Gujarat, Bihar, Gwalior, Jharkhand, Port-of-Spain, Hyderabad, Manama, Vadodara, Doha, Tripura, Hinganghat, Perth, Maharashtra, Gimhae-si, Chiyoda, Istanbul, Port, Kalyan, Kuwait City, Ankara, Al Khobar, Bhavnagar, London, Jakarta, Akola, Banswara, Nashik, Srinagar, Edmonton, Montreal, Los Angeles, Kolkata, Bundi, Rajasthan, Ballia, New Delhi, Seoul, Navi Mumbai, Mexico City, Madhya Pradesh, Amravati, Toronto, Ghaziabad, Asansol, Coimbatore, Kasganj, Nagaur, Milan, Melbourne, Sadar, Agra, Ranchi, Ernakulam, Chennai, Bhadreswar, Petaling Jaya, Ambattur, Dhanbad, Tadepalligudem, Jaipur, Durgapur, Miryalaguda, Mangalore, Nagapattinam, Ahvaz, Ajmer, Noida, Chhattisgarh, Gujarat, Madurai, Gorakhpur, Moscow, Brisbane, Puducherry, Punjab, Datia, Pune, Siliguri, Mumbai, Benin, Ulhasnagar, Amritsar, Pimpri and Chinchwad, Bhopal, Tehran, Kolapur, Sydney, Gulbarga, Lahore, Ujjain, Kota, Virar, Thane, Uttar Pradesh, Belgaum, Haora, Sharjah, Lucknow, Al Jubail, Kuala Lumpur, Karachi, Hubli and Dharwad, Nagda, Varanasi, Vasai, Bangalore, Surat, Raipur, Visakhapatnam, Bengaluru, Buxar, Jhansi, Bhiwadi.