- Steber Steel Solutions is the world's premier Exporter of Fittings, Flanges, Pipes, Sheet & Plate etc.

- sales@stebersteel.net

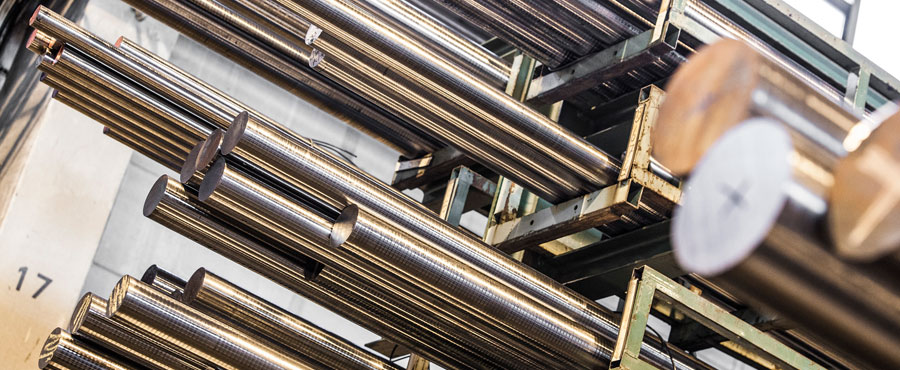

Monel K500 Round Bars

- home

- Monel Round Bar

Largest Stockists of Monel K500 Hex Bar, Monel K500 Round Bars, UNS N05500 Round Bars, Alloy K500 Round Rods, Biggest Monel Alloy K500 Rod, DIN 2.4375 Bright Bars Manufacturer In India.

Steber Steel Solutions is a well-known seller and trader of Monel Alloy K500 Round Bars, which are available at best prices for our esteemed customers.The aging treatment of Monel UNS N05500 Hollow Bars enhances its corrosion resistance by forming intermetallic precipitates that act as barriers against corrosion. However, it is important to select the appropriate aging temperature and duration to optimize both mechanical properties and corrosion resistance.

Before the final products are released for use, comprehensive verification processes are undertaken to ensure the quality and conformance of Monel WNR 2.4375 Hexagonal Bars. These verification processes include:

a. Dimensional Inspection: Final products are inspected for dimensional accuracy, including size, shape, and tolerances. This ensures that the components meet the required specifications and can be properly integrated into the intended applications.

b. Mechanical Testing: Mechanical tests, such as tensile testing, hardness testing, and impact testing, are conducted to assess the mechanical properties of the finished products. This verifies that the material possesses the desired strength, ductility, and toughness required for the intended use.

We provide the best quality Werkstoff 2.4375 Square Bar, UNS N05500 Forged Round Bar Specification Standard, Pure Monel K500 Hot Rolled Round Bar, Monel® Alloy K500 Cold Drawn Bar Stockist.

c. Corrosion Testing: Corrosion testing is performed to evaluate the corrosion resistance of this alloy in various corrosive environments. This ensures that the alloy can withstand the intended service conditions and maintain its performance over time.

d. Documentation and Traceability: Proper documentation, including material certifications, inspection reports, and traceability records, should be maintained to track the production process and provide assurance of the product's quality and compliance with relevant standards or specifications.

Quality control is a vital aspect of Nickel Alloy K500 Triangular Bars production to ensure the reliability, consistency, and performance of the alloy. Through meticulous raw material inspection, effective process control, non-destructive testing, and final product verification, the quality of this alloy can be maintained at a high standard. By adhering to strict quality control measures, manufacturers can ensure that the alloymeets the desired specifications, possesses the required mechanical properties and corrosion resistance, and provides reliable performance in diverse applications.

Monel K500 Round Bars Specifications

| Standard | ASTM B164, ASME SB164 |

| Round Bar Size | 3mm~ 800mm |

| Square Bar Size | 4mm* 4mm ~100mm* 100mm |

| Flat Bar Size | 2mm ~ 100mm |

| Hex Bar Size | 2mm ~ 100mm |

| Angle Size | 3mm* 20mm* 20mm~ 12mm* 100mm* 100mm |

| Thickness | 50 mm to 6000 mm Long |

| Length | 1 To 6 Meters, Custom Cut Length |

| Form | Round, Square, Hex(A/F), Rectangle, Billet, Ingot, Forging Etc |

Monel Round Bars Grades

Monel K500 Round Bars Types

Monel K500 Round Bars Equivalent Grade

| STANDARD | WERKSTOFF NR. | UNS | JIS | GOST | BS | AFNOR | EN |

| Monel K500 | 2.4375 | N05500 |

Buy Alloy K500 Round Bars online, Check ASME SB164 Monel K500 Round Rods Price List here. Stock of Monel Alloy K500 Hex Bar in Mumbai.

Monel K500 Round Bar Weight Chart

| Diameter | Weight Chart | Dia | Weight Chart |

|---|---|---|---|

| (mm) | per metre (kg) | (in) | per metre (kg) |

| 3mm | 0.06 | 1/8″ | 0.06 |

| 4mm | 0.10 | 3/16″ | 0.14 |

| 5mm | 0.16 | 1/4″ | 0.25 |

| 6mm | 0.22 | 5/16″ | 0.39 |

| 7mm | 0.30 | 3/8″ | 0.56 |

| 8mm | 0.40 | 7/16″ | 0.77 |

| 10mm | 0.62 | 1/2″ | 1.00 |

| 12mm | 0.89 | 9/16″ | 1.22 |

| 14mm | 1.22 | 5/8″ | 1.56 |

| 15mm | 1.40 | 11/16″ | 1.89 |

| 16mm | 1.59 | 3/4″ | 2.25 |

| 18mm | 2.01 | 7/8″ | 3.07 |

| 20mm | 2.48 | 1″ | 4.03 |

| 22mm | 3.00 | ||

| 24mm | 3.57 | ||

| 25mm | 3.88 |

Monel K500 Round Bar Size Chart

| Metric | US Bar | ASTM/ Canadian | Japanese | ||||

|---|---|---|---|---|---|---|---|

| Bar Size | Diam. (mm) | Bar Size | Diam. (Inch) | Bar Size | Diam. (mm2) | Bar Size | Diam. (mm) |

| 5 | 5 | #2 | 0.250 | 10M | 100 | 6 | 6 |

| 5.5 | 5.5 | #3 | 0.375 | 15M | 200 | 10 | 10 |

| 6 | 6 | #4 | 0.500 | 20M | 300 | 13 | 13 |

| 7 | 7 | #5 | 0.625 | 25M | 500 | 16 | 16 |

| 8 | 8 | #6 | 0.750 | 30M | 700 | 19 | 19 |

| 9 | 9 | #7 | 0.875 | 35M | 1000 | 22 | 22 |

| 10 | 10 | #8 | 1.000 | 45M | 1500 | 25 | 25 |

| 11 | 11 | #9 | 1.125 | 55M | 2500 | 29 | 29 |

| 12 | 12 | #10 | 1.250 | 32 | 32 | ||

| 14 | 14 | #11 | 1.375 | 35 | 35 | ||

| 16 | 16 | #12 | 1.500 | 38 | 38 | ||

| 18 | 18 | #13 | 1.625 | 41 | 41 | ||

| 20 | 20 | #14 | 1.750 | 44 | 44 | ||

| 22 | 22 | #15 | 1.875 | 48 | 48 | ||

| 25 | 25 | #16 | 2.000 | 51 | 51 | ||

| 28 | 28 | #18 | 2.250 | 57 | 57 | ||

| 32 | 32 | ||||||

| 36 | 36 | ||||||

| 40 | 40 | ||||||

| 44 | 44 | ||||||

| 50 | 50 | ||||||

Most Selling Types Of Monel K500 Round Bars

- Monel K500 Forged Rod

- Monel® Alloy K500 Flat Bar

- DIN 2.4375 Polished Flat Rod

- UNS N05500 Threaded Rods

- DIN 2.4375 Square Bar

- Monel WERKSTOFF NR. 2.4375 Forged Rods

- ASTM B164 Monel K500 Shaped bar

- UNS N05500 Triangular Rod

- K500 Monel Polished Round Bar

- Monel K500 Cold Drawn Bar

- ASME SB164 Alloy K500 Rectangular Rod Cold Drawn

- Monel Alloy K500 Square Rod

- UNS N05500 Bright Rod Cold Drawn

- Alloy K500 Hexangular Bars

- Monel K500 Roll Bar

- WERKSTOFF NR. 2.4375 Hex Bar

- ASTM B164 Monel K500 Cold Rolled Bright Bars

- Alloy K500 Hex Rod Cold Drawn Stockist

- Monel K500 Bright Bar

- UNS N05500 Rectangular Rod

- Monel K500 Square Rod Supplier

- Monel® Alloy K500 Round Bar

- UNS N05500 Round Bars

- UNS N05500 Hexagonal Bar

- Monel Alloy K500 Welding Rod

- Monel K500 Half-Round Bar Manufacturer

- K500 Monel Hot rolled Bright round bars

- Monel K500 Hexangular Rods

- UNS N05500 Hot Rolled Round Bar

- Alloy K500 Hollow Bar

- ASTM B164 Monel Alloy K500 Bar & Rods

- Alloy K500 Hex Bar

- Monel K500 Threaded Rod

- Monel Alloy K500 Bright Bars

- Alloy K500 Round Rods

- UNS N05500 T-Bar Stockholder

- DIN 2.4375 Bar

- Monel K500 Flat Bar Exporter

- Grade K500 Monel Flat Bar

- ASME SB164 Alloy K500 Rod

- Monel® Alloy K500 Rod

- Monel K500 Rectangle Bar Distributor

- Monel® Alloy K500 Bar

- DIN 2.4375 Bright Bars

- Monel Alloy K500 Washer

- Monel K500 Bright Bar Manufacturer

Monel K500 Round Bars Chemical Composition

| Grade | C | Mn | Si | Cu | Fe | Ni | S |

| Monel K500 | 0.25 max | 1.5 max | 0.5 max | 27.00 – 33.00 | 0.5 – 2 | 63.00 min | 0.010 max |

Monel K500 Round Bars Mechanical Properties

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.44 g/cm3 | 1350 °C (2460 °F) | Psi – 1,60,000 , MPa – 1100 | Psi – 1,15000 , MPa – 790 | 20% |

Best Supplier Of Monel K500 Round Bars in Following Countries

-

Exporting Monel Alloy K500 Round Bars to Below CountriesUkraine, Antananarivo, Austria, Spain, Accra, Kampala, Colombo, Mexico, UK, Jordan, Canada, Czech Republic, Taiwan, Libya, South Africa, Port Elizabeth, Lithuania, Greece, Finland, Switzerland, Omdurman, Mozabique, Estonia, Afghanistan, Maputo, Poland, Luanda, Russia, Benin, Bangladesh, Ethiopa, Subra al-Haymah, Portugal, Dakar, Iran, Tunisia, Cairo, Australia, UAE, Turkey, Japan, Italy, Brazil, Bolivia, Hong Kong, Sri Lanka, Giza, South Korea, Uganda, Lebanon, Lubumbashi, Netherlands, Iraq, Philippines, Houston, Colombia, Romania, Pretoria, Algeria, Dar es Salaam, Brazzaville, Mbuji-Mayi, Nairobi, Kolwezi, Belgium, Serbia, Port Harcourt, Myanmar, Jordon, Egypt, Addis Ababa, Israel, Bahrain, Cyprus, Tripoli, Kuwait, Kano, China, Croatia, United States, Douala, Lagos, Vietnam, Kenya, Abidjan, Netherland, Khartoum, Malaysia, South America, Saudi Arabia, Dubai, Mongolia, London, Gabon, Harare, Slovakia, Nigeria, Ouagadougou, Casablanca, Thailand (Bangkok), United Kingdom, Ecuador, Angola, Kazakhstan, Rabat, Yemen, Mogadishu, Sweden, Belarus, Austalia, Fez, Venezuela, Oman, Denmark, Mozambique, Johannesburg, United Arab Emirates, Africa, Phillipine, Bamako, India, Kuwait, Yaoundé, Azerbaijan, Kinshasa, Ghana, Durban, Costa Rica, Abu Dhabi, New Zealand, Trinidad and Tobago, Norway, Zaria, Ibadan, Bhutan, Germany, Kaduna, Indonesia, Conakry, Peru, Soweto, Freetown, Singapore, Morocco, Cameroon, Bulgaria, Chine, New York, Qatar, Cape Town, France, Sudan, Argentina, Bulawayo, Maiduguri, Hungary, Algiers, Alexandria, Pakistan.

-

Supplying Monel Alloy K500 Round Bars to Following Domestic CitiesBlair, Calgary, Ho Chi Minh City, Aberdeen, Andhra Pradesh, Bansberia, Riyadh, Ulsan, Jamalpur, Madrid, Kerala, Baraut, Vung Tau, Delhi, Betul, West Bengal, Suryapet, Jeddah, Aurangabad, Nagpur, Nanded, Orissa, Courbevoie, Granada, Manipur, Secunderabad, Rio de Janeiro, Ahmedabad, Ludhiana, Waghala, Muscat, Patna, Hanoi, Caracas, La Victoria, Allahabad, Busan, India, Atyrau, Loni, Ambala, Udgir, Haryana, Muktsar, Karnataka, Tamil Nadu, Kurnool, Chandigarh, Assam, Jamnagar, Thiruvananthapuram, Mizoram, Guntur, Jodhpur, Tirunelveli, Kanpur, Dombivali, Bikaner, Howrah, Bogota, Meerut, Saharanpur, Guwahati, Kalyani, Gurgaon, Jabalpur, Dammam, Dehradun, Faridabad, Solapur, Santiago, Indore, Rajkot, Geoje-si, Dallas, Vijayawada, Gujarat, Bihar, Gwalior, Jharkhand, Port-of-Spain, Hyderabad, Manama, Vadodara, Doha, Tripura, Hinganghat, Perth, Maharashtra, Gimhae-si, Chiyoda, Istanbul, Port, Kalyan, Kuwait City, Ankara, Al Khobar, Bhavnagar, London, Jakarta, Akola, Banswara, Nashik, Srinagar, Edmonton, Montreal, Los Angeles, Kolkata, Bundi, Rajasthan, Ballia, New Delhi, Seoul, Navi Mumbai, Mexico City, Madhya Pradesh, Amravati, Toronto, Ghaziabad, Asansol, Coimbatore, Kasganj, Nagaur, Milan, Melbourne, Sadar, Agra, Ranchi, Ernakulam, Chennai, Bhadreswar, Petaling Jaya, Ambattur, Dhanbad, Tadepalligudem, Jaipur, Durgapur, Miryalaguda, Mangalore, Nagapattinam, Ahvaz, Ajmer, Noida, Chhattisgarh, Gujarat, Madurai, Gorakhpur, Moscow, Brisbane, Puducherry, Punjab, Datia, Pune, Siliguri, Mumbai, Benin, Ulhasnagar, Amritsar, Pimpri and Chinchwad, Bhopal, Tehran, Kolapur, Sydney, Gulbarga, Lahore, Ujjain, Kota, Virar, Thane, Uttar Pradesh, Belgaum, Haora, Sharjah, Lucknow, Al Jubail, Kuala Lumpur, Karachi, Hubli and Dharwad, Nagda, Varanasi, Vasai, Bangalore, Surat, Raipur, Visakhapatnam, Bengaluru, Buxar, Jhansi, Bhiwadi.