- Steber Steel Solutions is the world's premier Exporter of Fittings, Flanges, Pipes, Sheet & Plate etc.

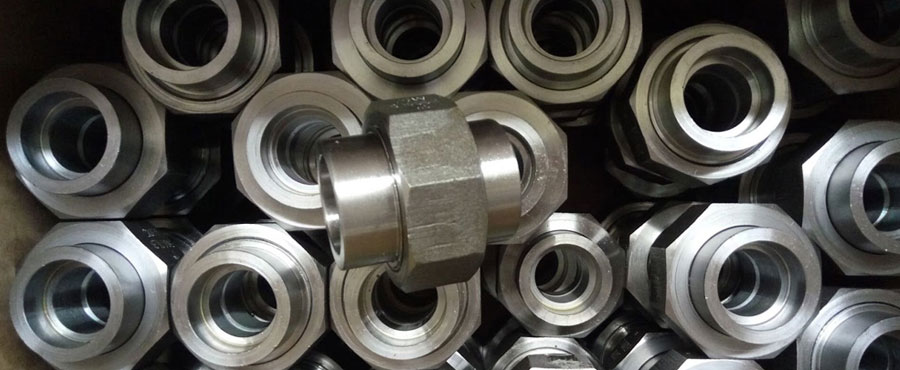

Monel K500 Socket Weld Fittings

- home

- Monel Socket Weld Fittings

Largest Stockists of UNS N05500 Socket Weld Cap, Monel K500 Socket Weld Cross, Biggest Monel Alloy K500 Socket Weld Fittings, Alloy K500 Socket Weld Elbow, DIN 2.4375 Socket Weld Union, Monel® Alloy K500 Socket Weld 90 degree Elbow Manufacturer In India.

Steber Steel Solutions is a well-known distributor and seller of Monel Alloy K500 Socket Weld Fittings, which consists of approximately 65-70% nickel, 29-33% copper, and small percentages of aluminum, titanium, and other trace elements.

The presence of aluminum and titanium in Monel UNS N05500 Socket Weld Fittings promotes the formation of intermetallic precipitates during the aging process, contributing to the alloy's increased strength. Alloy K-500 is resistant and ductile down to a temperature of -400°F, while its strength is maintained to 1200°F. To -200°F, it maintains its magnetic neutrality. In its annealed condition, Monel WNR 2.4375 Socket Weld Fittings exhibits a tensile strength of around 110,000 psi (760 MPa) and a hardness of approximately 180 HB. However, these properties can be significantly improved through the aging treatment.

We provide the best quality Monel K500 45 Deg Socket Weld Elbow, werkstoff 2.4375 Socket Weld Nipple, UNS N05500 Socket Weld Cross Specification Standard, Pure Monel Alloy K500 Socket Weld Fittings Stockist.

The aging treatment of Nickel Alloy K500 Socket Weld Fittings offers several key benefits, making it a crucial step in maximizing the alloy's performance:

Increased Strength: The aging process significantly increases the strength of Monel K500. It imparts a higher tensile strength, yield strength, and hardness to the alloy, allowing it to withstand greater loads and resist deformation under stress.

Improved Hardness: Aged Monel K500 exhibits enhanced hardness compared to its annealed state. The formation of intermetallic precipitates during aging contributes to an increase in hardness, providing improved wear resistance and surface durability.

Enhanced Corrosion Resistance: While Monel K500 already possesses excellent corrosion resistance, the aging treatment further enhances its ability to withstand aggressive environments. The precipitates formed during aging act as barriers against corrosion, improving the alloy's resistance to pitting, crevice corrosion, and stress corrosion cracking.

Retained Ductility: One significant advantage of the aging treatment is that it allows Monel K500 to retain its ductility despite the increase in strength. This combination of high strength and ductility is crucial in applications that require both load-bearing capacity and formability.

Monel Alloy K500 Socket Weld Fittings Specifications

| Specifications | ASTM B564 / ASME SB564 |

|---|---|

| Size | 1/8″ NB to 4″ NB Socket Weld |

| Dimensions | ASME 16.11, MSS SP-79, 83, 95, 97, BS 3799 |

| Class | 3000/ 6000/ 9000lbs |

| From | 90º Elbows, 45º Elbows, Tees, Cross, Couplings, Inserts, Caps, Nipples, Unions, Equal Tees & Reducing Tees.<0/td> |

Monel Socket Weld Fittings Grades

Monel K500 Socket Weld Fittings Types

Monel Alloy K500 Socket Weld Fittings Equivalent Grade

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Monel K500 | 2.4375 | N05500 | – | – | – | – | – |

Buy Monel Alloy K500 Socket Weld Pipe Elbow online, Check ASME SB564 Monel K500 Socket Weld Bushing Price List here. Stock of Monel Alloy K500 Socket Weld Fittings in Mumbai.

Monel K500 Socket Weld Fittings Dimensions in MM

| Nominal Pipe Size | 3000 PSI Rating | 6000 PSI Rating | |||||||||||

| IN | MM | Socket Bore B • | Socket Depth D | Socket Thickness | A | Body Bore * | G | Socket Thickness | A | Body Bore * | G | ||

| Average | MIN | Average | MIN | ||||||||||

| 1/4 | 06 | 14.1 | 09.65 | 3.78 | 3.30 | 11.2 | 10.0 | 3.02 | 04.60 | 4.00 | 13.5 | 07.10 | 3.68 |

| 3/8 | 10 | 17.5 | 09.65 | 4.00 | 3.50 | 13.5 | 13.3 | 3.20 | 05.03 | 4.37 | 15.8 | 09.90 | 4.00 |

| 1/2 | 15 | 21.7 | 09.65 | 4.67 | 4.10 | 15.8 | 16.6 | 3.75 | 05.97 | 5.18 | 19.0 | 12.06 | 4.78 |

| 3/4 | 20 | 27.0 | 09.65 | 4.90 | 4.27 | 19.0 | 21.7 | 3,91 | 06.96 | 6.05 | 22.3 | 1603 | 5.56 |

| 1 | 25 | 33.8 | 12.07 | 5.70 | 4.98 | 22.3 | 27.4 | 4.55 | 07.92 | 6.93 | 27.0 | 21.05 | 6.35 |

| 1 1/4 | 32 | 42.5 | 12.07 | 6.04 | 5.28 | 27.0 | 65.8 | 4.85 | 07.92 | 6.93 | 31.8 | 30.02 | 6.35 |

| 1 1/2 | 40 | 48.6 | 12.07 | 6.35 | 5.54 | 31.8 | 41.7 | 5.08 | 08.92 | 7.80 | 38.0 | 34.07 | 7.15 |

| 2 | 50 | 61.1 | 12.07 | 6.93 | 6,06 | 38.0 | 53.3 | 5.54 | 10.92 | 9.52 | 41.2 | 43.06 | 8.75 |

| 2 1/2 | 65 | 73.8 | 15.08 | 8.76 | 7.67 | 41.2 | 64.2 | 7.00 | |||||

| 3 | 80 | 89.8 | 15.08 | 9.50 | 8.30 | 57.2 | - | 7.68 | |||||

Weight Chart of Monel K500 Socket Weld Fittings

| Pipe Size | A | B | QTY | Weight Chart |

|---|---|---|---|---|

| ¼ | 0.81 | 0.88 | 160 | 0.20 |

| ⁄ | 0.97 | 1.00 | 130 | 0.26 |

| ½ | 1.12 | 1.31 | 100 | 0.57 |

| ¾ | 1.31 | 1.5 | 75 | 0.71 |

| 1 | 1.5 | 1.81 | 40 | 1.08 |

| 1 ¼ | 1.75 | 2.19 | 25 | 1.68 |

| 1 ½ | 2.00 | 2.44 | 18 | 2.38 |

| 2 | 2.38 | 2.97 | 10 | 3.55 |

| 2 ½ | 3.00 | 3.62 | 4 | 6.22 |

| 3 | 3.38 | 4.31 | 2 | 10.36 |

| 4 | 4.19 | 5.75 | 1 | 23.91 |

Most Selling Types Of Monel Alloy K500 Butt weld Socket Weld Fittings

- ASTM B564 Monel K500 Socket Weld Pipe Cap

- ASTM B564 Monel K500 Socket Weld 45 Degree Elbow

- Alloy K500 Socket Weld Full Coupling

- Monel K500 Socket Weld Elbow

- UNS N05500 Socket Weld Fittings

- Monel K500 Socket Weld Hex Plug

- Monel Alloy K500 Socket Weld Union

- Monel K500 Socket Weld Cross

- UNS N05500 Socket Weld Hex Plug

- DIN 2.4375 Socket Weld Fittings

- Monel® Alloy K500 Socket Weld 45 deg Elbow

- ANSI B16.11 Monel K500 Socket Weld Plug

- Monel K500 Socket Weld Coupling

- UNS N05500 Socket Weld Equal Tee

- DIN 2.4375 Socket Weld Tee

- DIN 2.4375 Socket Weld Pipe Elbow

- UNS N05500 Socket Weld Elbow

- WERKSTOFF NR. 2.4375 Socket Weld Equal Tee

- ASME SB564 Alloy K500 Socket Weld Lateral Tee

- Monel Alloy K500 Socket Weld Fittings Supplier

- Grade K500 Monel Socket Weld Reducing Tee

- Monel WERKSTOFF NR. 2.4375 Socket Weld Fittings

- Alloy K500 Socket Weld Bushing Stockist

- Monel® Alloy K500 Socket Weld Pipe Nipple

- Alloy K500 Socket Weld Union

- UNS N05500 Socket Weld Pipe Nipple

- Monel Alloy K500 Socket Weld Cross

- UNS N05500 Socket Weld Coupling

- Monel K500 45 Degree Socket Weld Elbow Manufacturer

- UNS N05500 45 Deg Socket Weld Elbow

- ASME B16.11 Monel K500 Socket Weld Reducing Cross

- Monel Alloy K500 Socket Weld Unequal Tee Exporter

- UNS N05500 Socket Weld Elbow Stockholder

- ASME SB564 Alloy K500 Socket Weld Cap

- ANSI B16.11 Monel® Alloy K500 Socket Weld Elbow

- Monel K500 Socket Weld Fittings Manufacturer

- DIN 2.4375 90 Degree Socket Weld Elbow

- Monel® Alloy K500 Socket Weld Union

- ASTM B564 Monel Alloy K500 Socket Weld Fittings

- ANSI B16.11 Monel K500 Socket Weld Fittings

- Grade K500 Monel Socket Weld Reducing Cross

- Alloy K500 Socket Weld Tee

- Monel Alloy K500 Socket Weld Plug

- UNS N05500 Socket Weld Elbow

- Monel K500 Socket Weld End Cap Distributor

- Alloy K500 Socket Weld Equal Cross

Monel K500 Socket Weld Fittings Chemical Composition

| Grade | C | Mn | Si | P | S | Cu | Mo | Ni | Fe |

| Monel K500 | 0.25 max | 1.5 max | 0.50 max | – | 0.010 max | 27 – 33 | – | 63.00 min | 0.5-2 max |

Monel Alloy K500 Socket Weld Fittings Mechanical Properties

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.44 g/cm3 | 1350 °C (2550 °F) | Psi – 160000 , MPa – 1100 | Psi – 115000 , MPa – 790 | 20 % |

Best Supplier Of Monel K500 Socket Weld Fittings in Following Countries

-

Exporting Monel K500 Socket Weld Fittings to Below CountriesUkraine, Antananarivo, Austria, Spain, Accra, Kampala, Colombo, Mexico, UK, Jordan, Canada, Czech Republic, Taiwan, Libya, South Africa, Port Elizabeth, Lithuania, Greece, Finland, Switzerland, Omdurman, Mozabique, Estonia, Afghanistan, Maputo, Poland, Luanda, Russia, Benin, Bangladesh, Ethiopa, Subra al-Haymah, Portugal, Dakar, Iran, Tunisia, Cairo, Australia, UAE, Turkey, Japan, Italy, Brazil, Bolivia, Hong Kong, Sri Lanka, Giza, South Korea, Uganda, Lebanon, Lubumbashi, Netherlands, Iraq, Philippines, Houston, Colombia, Romania, Pretoria, Algeria, Dar es Salaam, Brazzaville, Mbuji-Mayi, Nairobi, Kolwezi, Belgium, Serbia, Port Harcourt, Myanmar, Jordon, Egypt, Addis Ababa, Israel, Bahrain, Cyprus, Tripoli, Kuwait, Kano, China, Croatia, United States, Douala, Lagos, Vietnam, Kenya, Abidjan, Netherland, Khartoum, Malaysia, South America, Saudi Arabia, Dubai, Mongolia, London, Gabon, Harare, Slovakia, Nigeria, Ouagadougou, Casablanca, Thailand (Bangkok), United Kingdom, Ecuador, Angola, Kazakhstan, Rabat, Yemen, Mogadishu, Sweden, Belarus, Austalia, Fez, Venezuela, Oman, Denmark, Mozambique, Johannesburg, United Arab Emirates, Africa, Phillipine, Bamako, India, Kuwait, Yaoundé, Azerbaijan, Kinshasa, Ghana, Durban, Costa Rica, Abu Dhabi, New Zealand, Trinidad and Tobago, Norway, Zaria, Ibadan, Bhutan, Germany, Kaduna, Indonesia, Conakry, Peru, Soweto, Freetown, Singapore, Morocco, Cameroon, Bulgaria, Chine, New York, Qatar, Cape Town, France, Sudan, Argentina, Bulawayo, Maiduguri, Hungary, Algiers, Alexandria, Pakistan.

-

Supplying Monel K500 Socket Weld Fittings to Following Domestic CitiesBlair, Calgary, Ho Chi Minh City, Aberdeen, Andhra Pradesh, Bansberia, Riyadh, Ulsan, Jamalpur, Madrid, Kerala, Baraut, Vung Tau, Delhi, Betul, West Bengal, Suryapet, Jeddah, Aurangabad, Nagpur, Nanded, Orissa, Courbevoie, Granada, Manipur, Secunderabad, Rio de Janeiro, Ahmedabad, Ludhiana, Waghala, Muscat, Patna, Hanoi, Caracas, La Victoria, Allahabad, Busan, India, Atyrau, Loni, Ambala, Udgir, Haryana, Muktsar, Karnataka, Tamil Nadu, Kurnool, Chandigarh, Assam, Jamnagar, Thiruvananthapuram, Mizoram, Guntur, Jodhpur, Tirunelveli, Kanpur, Dombivali, Bikaner, Howrah, Bogota, Meerut, Saharanpur, Guwahati, Kalyani, Gurgaon, Jabalpur, Dammam, Dehradun, Faridabad, Solapur, Santiago, Indore, Rajkot, Geoje-si, Dallas, Vijayawada, Gujarat, Bihar, Gwalior, Jharkhand, Port-of-Spain, Hyderabad, Manama, Vadodara, Doha, Tripura, Hinganghat, Perth, Maharashtra, Gimhae-si, Chiyoda, Istanbul, Port, Kalyan, Kuwait City, Ankara, Al Khobar, Bhavnagar, London, Jakarta, Akola, Banswara, Nashik, Srinagar, Edmonton, Montreal, Los Angeles, Kolkata, Bundi, Rajasthan, Ballia, New Delhi, Seoul, Navi Mumbai, Mexico City, Madhya Pradesh, Amravati, Toronto, Ghaziabad, Asansol, Coimbatore, Kasganj, Nagaur, Milan, Melbourne, Sadar, Agra, Ranchi, Ernakulam, Chennai, Bhadreswar, Petaling Jaya, Ambattur, Dhanbad, Tadepalligudem, Jaipur, Durgapur, Miryalaguda, Mangalore, Nagapattinam, Ahvaz, Ajmer, Noida, Chhattisgarh, Gujarat, Madurai, Gorakhpur, Moscow, Brisbane, Puducherry, Punjab, Datia, Pune, Siliguri, Mumbai, Benin, Ulhasnagar, Amritsar, Pimpri and Chinchwad, Bhopal, Tehran, Kolapur, Sydney, Gulbarga, Lahore, Ujjain, Kota, Virar, Thane, Uttar Pradesh, Belgaum, Haora, Sharjah, Lucknow, Al Jubail, Kuala Lumpur, Karachi, Hubli and Dharwad, Nagda, Varanasi, Vasai, Bangalore, Surat, Raipur, Visakhapatnam, Bengaluru, Buxar, Jhansi, Bhiwadi.