- Steber Steel Solutions is the world's premier Exporter of Fittings, Flanges, Pipes, Sheet & Plate etc.

Hastelloy B2 Olets

- home

- Hastelloy Olets

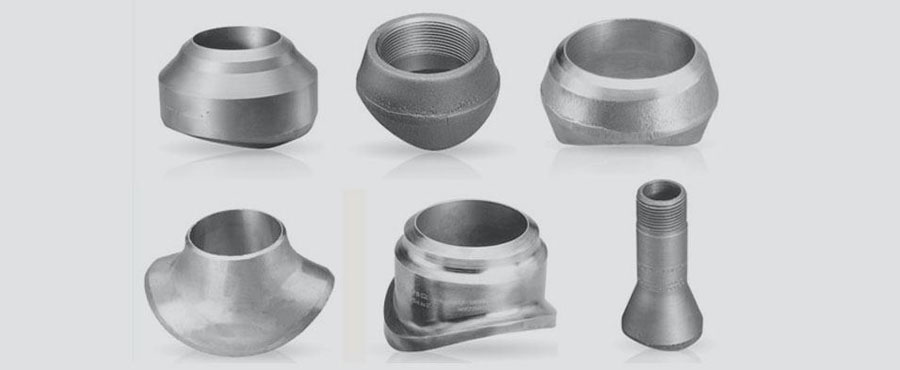

Largest Stockists of Hastelloy B2 Olets, Hastelloy B2 Welding Outlet, Alloy B2 Brazolet, Biggest Hastelloy Alloy B2 Threadolet, DIN 2.4617 Nipple Outlets, UNS N10665 Olets Manufacturer In India.

Steber Steel Solutions is a recognised exporter and supplier of Hastelloy Alloy B2 Olets, which is a corrosion-resistant super alloy and finds extensive use in the aerospace industry due to its exceptional properties and reliability. Aerospace applications demand materials that can withstand extreme temperatures, corrosive environments, and mechanical stress.

Molybdenum provides Hastelloy UNS N10665 Brazolets with excellent resistance to reducing environments and helps prevent corrosion in acidic and chloride-containing solutions. It also enhances the alloy's resistance to pitting and crevice corrosion, making it suitable for aggressive petrochemical applications.The presence of tungsten and nickel further enhances the alloy's resistance to corrosion in sulphuric acid, hydrochloric acid, and other corrosive media commonly found in petrochemical processes.

We provide the best quality UNS N10665 Outlet Fittings Specification Standard, Hastelloy® Alloy B2 Latrolets, Pure Hastelloy B2 Nipple Outlets, Werkstoff 2.4617 Olets Fittings Stockist.

Power plants need effective exhaust systems to manage emissions and comply with environmental regulations. Hastelloy WNR 2.4617 Weldolets is used in exhaust systems to withstand the corrosive gases and high temperatures generated by power generation processes. Additionally, it is employed in FGD systems for its resistance to sulphuric acid and other corrosive substances produced during flue gas treatment.

Hastelloy B2's remarkable corrosion resistance, high-temperature stability, and mechanical properties make it an indispensable material in the power generation industry. Its usage in gas turbines, heat exchangers, boiler systems, exhaust systems, and FGD systems significantly enhances reliability, performance, and longevity. By incorporating Hastelloy B2, power plants can ensure efficient operation, minimize downtime, and adhere to stringent environmental standards, contributing to sustainable and reliable power generation. Hastelloy B2's exceptional corrosion resistance, high-temperature stability, and mechanical properties make it a valuable material in the aerospace industry. Its usage in engine components, gas turbine engines, structural components, and various aerospace applications enhances performance, reliability, and safety. By incorporating Nickel Alloy B2 Sockolets, aerospace manufacturers and operators can ensure the longevity and integrity of critical components, contributing to the advancement and success of the aerospace industry.

Hastelloy B2 Olets Specifications

| Specifications | ASTM B366/ ASME SB366 |

|---|---|

| Dimensions | ASME / ANSI B16.11, MSS-SP-97, MSS-SP-79, JIS B2316, BS 3799 etc |

| Size | 1/8"-4" (DN6-DN100) |

| Connect Type | Welded, threaded, BW, SW |

| Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Specialized Manufacturer of | Weldolets, Threadolets, Sockolets, Elbolets, Elbolets, Nippolets, Lateral Outlet, Coupolet, Flexolet, Sweepolet, Brazolet |

| We provide Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |

Hastelloy Olets Grades

Hastelloy B2 Olets Types

Hastelloy B2 Olets Equivalent Grade

| STANDARD | UNS | WERKSTOFF NR. |

| Hastelloy B2 | N10665 | 2.4617 |

Buy Alloy B2 Olets online, Check ASME SB366 Hastelloy B2 Threading Outlet Price List here. Stock of Hastelloy Alloy B2 Sockolet in Mumbai.

Hastelloy B2 Weldolet Dimensions

| NPS | A | B | C | D |

|---|---|---|---|---|

| 1 | 1.1/16 26.99 |

2 50.80 |

1.7/16 36.51 |

1.1/32 26.19 |

| 1/2 | 3/4 19.05 |

1.3/8 34.93 |

15/16 23.81 |

5/8 15.88 |

| 3/4 | 7/8 22.23 |

1.5/8 41.28 |

1.3/16 30.16 |

13/16 20.64 |

| 1¼ | 1¼ 31.75 |

2.3/8 60.3 |

1.3/4 44.45 |

1.3/8 34.93 |

| 1½ | 1.5/16 33.34 |

2.7/8 73 |

2 50.80 |

1.5/8 41.28 |

| 2 | 1½ 38.10 |

3½ 88.90 |

2.9/16 65.09 |

2.1/16 52.39 |

| 2½ | 1.5/8 41.28 |

4.1/16 103.19 |

3 76.20 |

2.7/16 61.91 |

| 3 | 1.3/4 44.45 |

4.13/16 122.24 |

3.11/16 93.66 |

3.1/16 77.79 |

| 3½ | 2 50.80 |

5.3/8 136.53 |

3.7/8 98.43 |

3.9/16 90.49 |

| 4 | 2 50.80 |

6 152.40 |

4.3/4 120.65 |

4 101.60 |

| 5 | 2¼ 57.15 |

7.1/8 180.98 |

5.9/16 141.29 |

5.1/16 128.59 |

| 6 | 2.3/8 60.3 |

8½ 215.90 |

6.11/16 169.86 |

6.1/16 153.99 |

| 8 | 2.3/4 69.85 |

10.3/8 263.53 |

8.11/16 220.66 |

7.15/16 201.61 |

| 10 | 3.1/16 77.79 |

12.9/16 319.09 |

10.13/16 274.64 |

10 254.00 |

| 12 | 3.3/8 85.73 |

14.7/8 377.83 |

12.13/16 325.44 |

12 304.80 |

| 14 | 3½ 88.90 |

16.1/8 409.58 |

14.1/16 357.19 |

13¼ 336.55 |

| 16 | 3.11/16 93.66 |

18¼ 463.55 |

16.1/16 407.99 |

15¼ 387.35 |

| 18 | 4.1/16 103.19 |

20.3/4 527.05 |

18.5/8 473.08 |

17¼ 438.15 |

| 20 | 4.5/8 117.48 |

23.1/16 585.79 |

20.1/16 509.59 |

19¼ 488.95 |

| 24 | 5.3/8 136.53 |

27.7/8 708.03 |

25.1/8 638.18 |

23¼ 590.55 |

| NPS | A | B | C | D |

Hastelloy B2 Sockolet Dimensions

| Nominal Pipe Size | Socket (C) Minimum |

Face to Crotch (L) | |

| 3000 Lbs | 6000 Lbs | ||

| 1″ | 13 | 22 | 29 |

| 1/8″ | 10 | 10 | – |

| 1/4″ | 10 | 10 | – |

| 3/8″ | 10 | 13 | – |

| 1/2″ | 10 | 16 | 24 |

| 3/4″ | 13 | 16 | 25 |

| 1 1/4″ | 13 | 22 | 30 |

| 1 1/2″ | 13 | 24 | 32 |

| 2″ | 16 | 24 | 37 |

| 2 1/2″ | 16 | 25 | – |

| 3″ | 16 | 30 | – |

| 4″ | 19 | 30 | – |

Hastelloy B2 Threadolet Dimensions

| Nominal Pipe Size | Face to Crotch (L) | |

| 3000 Lbs | 6000 Lbs | |

| 1″ | 33 | 40 |

| 1/8″ | 19 | – |

| 1/4″ | 19 | – |

| 3/8″ | 21 | – |

| 1/2″ | 25 | 32 |

| 3/4″ | 27 | 37 |

| 1 1/4″ | 33 | 41 |

| 1 1/2″ | 35 | 43 |

| 2″ | 38 | 52 |

| 2 1/2″ | 46 | – |

| 3″ | 51 | – |

| 4″ | 57 | – |

Hastelloy B2 Nipolet Dimensions

| Nominal Pipe Size | Face to Crotch (L) | |

| 3000 Lbs | 6000 Lbs | |

| 1/2″ | 25 | 32 |

| 3/4″ | 27 | 37 |

| 1 1/4″ | 33 | 41 |

| 1″ | 33 | 40 |

| 1/8″ | 19 | – |

| 1/4″ | 19 | – |

| 3/8″ | 21 | – |

| 1 1/2″ | 35 | 43 |

| 2″ | 38 | 52 |

| 2 1/2″ | 46 | – |

| 3″ | 51 | – |

| 4″ | 57 | – |

Hastelloy B2 Latrolet Dimensions

| Nominal Pipe Size | Face to Crotch (L) | |

| 3000 Lbs | 6000 Lbs | |

| 1/8″ | 19 | – |

| 1/4″ | 19 | – |

| 3/8″ | 21 | – |

| 1/2″ | 25 | 32 |

| 3/4″ | 27 | 37 |

| 1″ | 33 | 40 |

| 1 1/4″ | 33 | 41 |

| 1 1/2″ | 35 | 43 |

| 2″ | 38 | 52 |

| 2 1/2″ | 46 | – |

| 3″ | 51 | – |

| 4″ | 57 | – |

Hastelloy B2 Latrolet Dimensions

| Nominal Elbow Size Inches |

Outlet Size Inches |

Dimensions | |||

| CL 3000 Threaded & Socket Weld Std. & XS Butt-Weld |

CL 6000 Threaded & Socket Socket-Weld Sch. 160 & XXS Butt-Weld |

||||

| C | E | C | E | ||

| 36 – 3/4 | 3/8 | 1 1/2 | 1 19/32 | 1 1/2 | 1 19/32 |

| 36 – 3/4 | 1/2 | 1 1/2 | 1 19/32 | 1 23/32 | 1 7/8 |

| 36 – 1 | 3/4 | 1 23/32 | 1 7/8 | 2 1/4 | 2 1/4 |

| 36 – 3/4 | 1/4 | 1 1/2 | 1 19/32 | 1 1/2 | 1 19/32 |

| 36 – 2 | 1 | 2 1/4 | 2 1/4 | 2 7/8 | 2 1/2 |

| 36 – 2 | 1 1/4 | 2 7/8 | 2 1/2 | 3 1/8 | 2 11/16 |

| 36 – 2 | 1 1/2 | 3 1/8 | 2 11/16 | 4 3/16 | 3 1/4 |

| 36 – 3 | 2 | 4 3/16 | 3 1/4 | ||

| **2 1/2 | 4 3/16 | 3 1/4 | |||

| **3 | 5 1/16 | 3 7/8 | |||

| Order to Specific | **4 | 6 5/8 | 4 13/16 | ||

| Elbow Sizes | **6 | 9 3/8 | 6 1/2 | ** | ** |

| **8 | 13 5/16 | 8 1/16 | |||

| **10 | 17 1/32 | 10 3/8 | |||

| **12 | 19 5/8 | 11 1/8 | |||

Most Selling Types Of Hastelloy Alloy B2 Olets

- Hastelloy B2 Latrolet

- UNS N10665 Swept Outlet

- Grade B2 Hastelloy Flexolet

- DIN 2.4617 Sweepolet

- Alloy B2 Threadolet

- Hastelloy B2 Threading Outlet

- DIN 2.4617 Nippolet

- UNS N10665 Socket Weld Olets

- Hastelloy® Alloy B2 Latrolet

- Hastelloy B2 Coupolet Supplier

- ASTM B366 Hastelloy B2 Welding Outlet

- Hastelloy Alloy B2 Elbow Outlets

- UNS N10665 Threaded Outlet

- Hastelloy® Alloy B2 Elbolet

- B2 Hastelloy Socket Weld Outlets

- ASTM B366 Hastelloy B2 Weldolet

- ASME SB366 Alloy B2 Threadolet

- Hastelloy WERKSTOFF NR. 2.4617 Sockolet

- WERKSTOFF NR. 2.4617 Nipple Outlets

- UNS N10665 Flexolet

- Alloy B2 Insert Weld Outlet Stockist

- Hastelloy B2 Outlets Fittings

- Hastelloy B2 Lateral Outlet

- DIN 2.4617 Nipple Olets

- UNS N10665 Socket Weld Outlet

- Hastelloy B2 Branch Outlets

- Grade B2 Hastelloy Socket Weld Outlet

- B2 Hastelloy Olets

- Hastelloy Alloy B2 Outlets Fittings

- DIN 2.4617 Threading Outlet

- UNS N10665 Flangeolet

- Hastelloy B2 Latrolet Manufacturer

- ASME SB366 Alloy B2 Olets

- Alloy B2 Branch Outlets

- UNS N10665 Welding Olets

- Alloy B2 Full Flexolet

- Hastelloy B2 Olets Distributor

- ASTM B366 Hastelloy Alloy B2 Coupolet

- Hastelloy B2 Olets

- Hastelloy B2 Threadolet Manufacturer

- Alloy B2 Latrolet

- Hastelloy Alloy B2 Outlets

- UNS N10665 Nippolet Stockholder

- UNS N10665 Sockolet

- Hastelloy® Alloy B2 Lateral Olets

- Hastelloy B2 Brazolet Exporter

Hastelloy B2 Olets Chemical Composition

| Hastelloy B2 | Ni | C | Mo | Mn | Si | Fe | P | S | Co | Cr |

| Balance | 0.02 max | 26.0-30.0 | 1.0 max | 0.10 max | 2.0 max | 0.040 max | 0.030 max | 1.0 max | 1.0 max |

Hastelloy B2 Olets Mechanical Properties

Best Supplier Of Hastelloy B2 Olets in Following Countries

-

Exporting Hastelloy B2 Olets to Below CountriesUkraine, Antananarivo, Austria, Spain, Accra, Kampala, Colombo, Mexico, UK, Jordan, Canada, Czech Republic, Taiwan, Libya, South Africa, Port Elizabeth, Lithuania, Greece, Finland, Switzerland, Omdurman, Mozabique, Estonia, Afghanistan, Maputo, Poland, Luanda, Russia, Benin, Bangladesh, Ethiopa, Subra al-Haymah, Portugal, Dakar, Iran, Tunisia, Cairo, Australia, UAE, Turkey, Japan, Italy, Brazil, Bolivia, Hong Kong, Sri Lanka, Giza, South Korea, Uganda, Lebanon, Lubumbashi, Netherlands, Iraq, Philippines, Houston, Colombia, Romania, Pretoria, Algeria, Dar es Salaam, Brazzaville, Mbuji-Mayi, Nairobi, Kolwezi, Belgium, Serbia, Port Harcourt, Myanmar, Jordon, Egypt, Addis Ababa, Israel, Bahrain, Cyprus, Tripoli, Kuwait, Kano, China, Croatia, United States, Douala, Lagos, Vietnam, Kenya, Abidjan, Netherland, Khartoum, Malaysia, South America, Saudi Arabia, Dubai, Mongolia, London, Gabon, Harare, Slovakia, Nigeria, Ouagadougou, Casablanca, Thailand (Bangkok), United Kingdom, Ecuador, Angola, Kazakhstan, Rabat, Yemen, Mogadishu, Sweden, Belarus, Austalia, Fez, Venezuela, Oman, Denmark, Mozambique, Johannesburg, United Arab Emirates, Africa, Phillipine, Bamako, India, Kuwait, Yaoundé, Azerbaijan, Kinshasa, Ghana, Durban, Costa Rica, Abu Dhabi, New Zealand, Trinidad and Tobago, Norway, Zaria, Ibadan, Bhutan, Germany, Kaduna, Indonesia, Conakry, Peru, Soweto, Freetown, Singapore, Morocco, Cameroon, Bulgaria, Chine, New York, Qatar, Cape Town, France, Sudan, Argentina, Bulawayo, Maiduguri, Hungary, Algiers, Alexandria, Pakistan.

-

Supplying Hastelloy B2 Olets to Following Domestic CitiesBlair, Calgary, Ho Chi Minh City, Aberdeen, Andhra Pradesh, Bansberia, Riyadh, Ulsan, Jamalpur, Madrid, Kerala, Baraut, Vung Tau, Delhi, Betul, West Bengal, Suryapet, Jeddah, Aurangabad, Nagpur, Nanded, Orissa, Courbevoie, Granada, Manipur, Secunderabad, Rio de Janeiro, Ahmedabad, Ludhiana, Waghala, Muscat, Patna, Hanoi, Caracas, La Victoria, Allahabad, Busan, India, Atyrau, Loni, Ambala, Udgir, Haryana, Muktsar, Karnataka, Tamil Nadu, Kurnool, Chandigarh, Assam, Jamnagar, Thiruvananthapuram, Mizoram, Guntur, Jodhpur, Tirunelveli, Kanpur, Dombivali, Bikaner, Howrah, Bogota, Meerut, Saharanpur, Guwahati, Kalyani, Gurgaon, Jabalpur, Dammam, Dehradun, Faridabad, Solapur, Santiago, Indore, Rajkot, Geoje-si, Dallas, Vijayawada, Gujarat, Bihar, Gwalior, Jharkhand, Port-of-Spain, Hyderabad, Manama, Vadodara, Doha, Tripura, Hinganghat, Perth, Maharashtra, Gimhae-si, Chiyoda, Istanbul, Port, Kalyan, Kuwait City, Ankara, Al Khobar, Bhavnagar, London, Jakarta, Akola, Banswara, Nashik, Srinagar, Edmonton, Montreal, Los Angeles, Kolkata, Bundi, Rajasthan, Ballia, New Delhi, Seoul, Navi Mumbai, Mexico City, Madhya Pradesh, Amravati, Toronto, Ghaziabad, Asansol, Coimbatore, Kasganj, Nagaur, Milan, Melbourne, Sadar, Agra, Ranchi, Ernakulam, Chennai, Bhadreswar, Petaling Jaya, Ambattur, Dhanbad, Tadepalligudem, Jaipur, Durgapur, Miryalaguda, Mangalore, Nagapattinam, Ahvaz, Ajmer, Noida, Chhattisgarh, Gujarat, Madurai, Gorakhpur, Moscow, Brisbane, Puducherry, Punjab, Datia, Pune, Siliguri, Mumbai, Benin, Ulhasnagar, Amritsar, Pimpri and Chinchwad, Bhopal, Tehran, Kolapur, Sydney, Gulbarga, Lahore, Ujjain, Kota, Virar, Thane, Uttar Pradesh, Belgaum, Haora, Sharjah, Lucknow, Al Jubail, Kuala Lumpur, Karachi, Hubli and Dharwad, Nagda, Varanasi, Vasai, Bangalore, Surat, Raipur, Visakhapatnam, Bengaluru, Buxar, Jhansi, Bhiwadi.